The TELSEC Chronicle

Deep Dive

Exploring the critical issues facing today's infrastructure operators.

Lead/Lag Controllers in HVAC Systems: Enhancing Efficiency and Reliability

Lead/lag controllers play an essential role in optimizing the performance and efficiency of HVAC (Heating, Ventilation, and Air Conditioning) systems. These controllers manage the operation of multiple components, such as pumps, compressors, or fans, in a coordinated way to ensure balanced performance, energy efficiency, and system reliability.

The Function of Lead/Lag Controllers in HVAC

In an HVAC system, lead/lag controllers are primarily used to manage the switching between multiple equipment units to ensure that the system maintains optimal operation without overburdening any single unit. In a typical scenario, a "lead" unit is the first to operate, while one or more "lag" units are brought online as needed to meet increased demand or prevent system overloads.

The main advantage of using a lead/lag control strategy in HVAC systems is to balance wear and tear across multiple units, which improves equipment longevity and reliability. It also helps in energy management by ensuring that no unit is running unnecessarily or at a suboptimal capacity.

Note: Lead/lag controllers are only effective when all HVAC units are supplying the same space.

Lead and Lag Control Strategies

Lead Control: The lead unit is the first to activate, responding to the HVAC system’s demand for heating, cooling, or ventilation. The lead controller ensures the system reacts promptly to changes in temperature, humidity, or airflow, providing quick responses to varying load conditions.

Lag Control: As the system demand increases, the lag unit(s) come online in sequence to provide additional capacity. Lag units are typically only activated when the lead unit cannot meet the required performance on its own. This not only prevents system strain but also allows for better energy use by preventing unnecessary activation of multiple units.

By rotating between the lead and lag units, HVAC systems also ensure that no single unit is overused, which helps prevent equipment failure and extends the life of each component.

Benefits of Lead/Lag Controllers in HVAC Systems

Improved Energy Efficiency: By ensuring that only the necessary units are running, lead/lag controllers help to avoid excess energy consumption and minimize operational costs.

Extended Equipment Life: By balancing the load between multiple units, wear and tear are more evenly distributed, reducing the chances of breakdowns and prolonging the lifespan of HVAC equipment.

Increased System Reliability: Lead/lag control helps avoid overloading and ensures that the HVAC system maintains performance under varying conditions, making it more reliable and less prone to failure.

Enhanced System Flexibility: With the ability to dynamically adjust which units are operating, HVAC systems can be more responsive to changes in building load or external environmental conditions.

Quest Controls Lead/Lag Controllers

Quest Controls offers a range of advanced lead/lag controllers specifically designed for HVAC systems. These controllers are engineered to optimize the performance of HVAC equipment by ensuring efficient operation, reducing energy waste, and increasing overall system longevity.

Quest’s lead/lag controllers are highly customizable, allowing for tailored configurations that meet the specific demands of various HVAC applications. With user-friendly interfaces, real-time monitoring, and adaptive control capabilities, Quest Controls ensures that HVAC systems run efficiently and reliably, all while maintaining optimal performance and energy use.

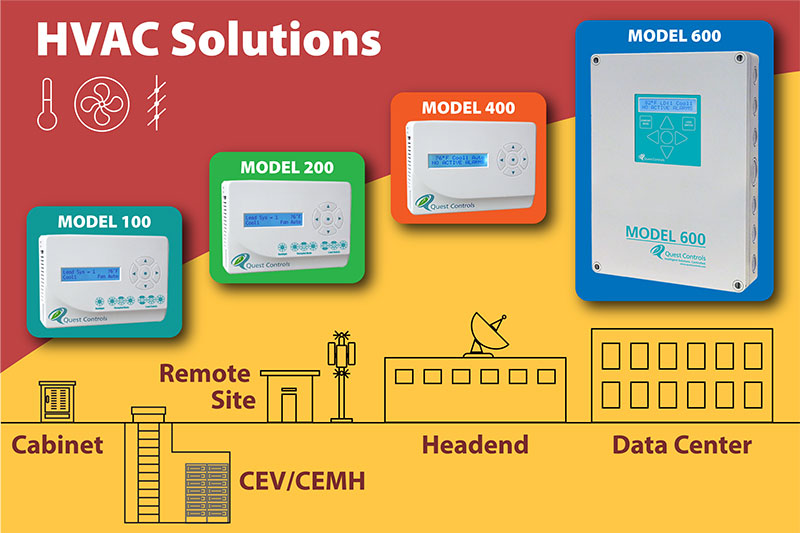

Quest Specific HVAC Controllers: Models 600, 400, 200 & 100

Quest Controls provides a variety of controllers designed for HVAC systems, each tailored to meet the needs of different operational scales and performance requirements. These models include:

- Model 600: A smart, budget-friendly automation solution tailored for the specific requirements of telecom and broadband critical facilities. It serves as the central controller for your HVAC system, offering extensive monitoring and control for MULTIPLE HVAC units. With remote communication capabilities, it’s ideal for small to medium-sized facilities, cabinets, and remote shelters.

- Model 400: An advanced HVAC control system designed for medium and large facilities. It can operate independently or alongside the TELSEC® ESB2 Environmental Controller. With features like lead/lag/standby functionality and patented economizer control, it ensures precise temperature management while maximizing energy efficiency. Ideal for a range of HVAC setups, the Model 400 is the perfect solution for maintaining optimal climate conditions in critical environments.

- Model 100/101 & 200/201: Low-cost and easy replacements for traditional lead/lag controls, optimizing operation and reducing energy consumption.

Quest Controls’ lead/lag controllers, including the 600, 400, 200, and 100 models, are designed to provide precise and efficient control for a wide range of HVAC applications. Whether for a large commercial complex or a smaller residential system, Quest's HVAC controllers offer the flexibility and performance necessary to ensure energy efficiency, extended equipment life, and improved overall system reliability.